Digitisation in Construction Equipment Industry- 2

The construction equipment industry has seen a remarkable transformation in recent years, thanks to the rise of digitisation. From smart equipment to connected job sites, the entire value chain is becoming more integrated, data-driven, and efficient. One of the key areas driving this change is digitisation in operations . This encompasses the integration of various digital tools and systems that streamline workflows, reduce manual intervention, and enable real-time decision-making.

In this blog, we will explore in depth the ways in which digitisation is revolutionising operations in the construction equipment industry, with a focus on key innovations such as Integrated Dealer Management Systems, Mobile Apps for CRM, Self-Service Customer Apps, and Telematics for Fleet Management.

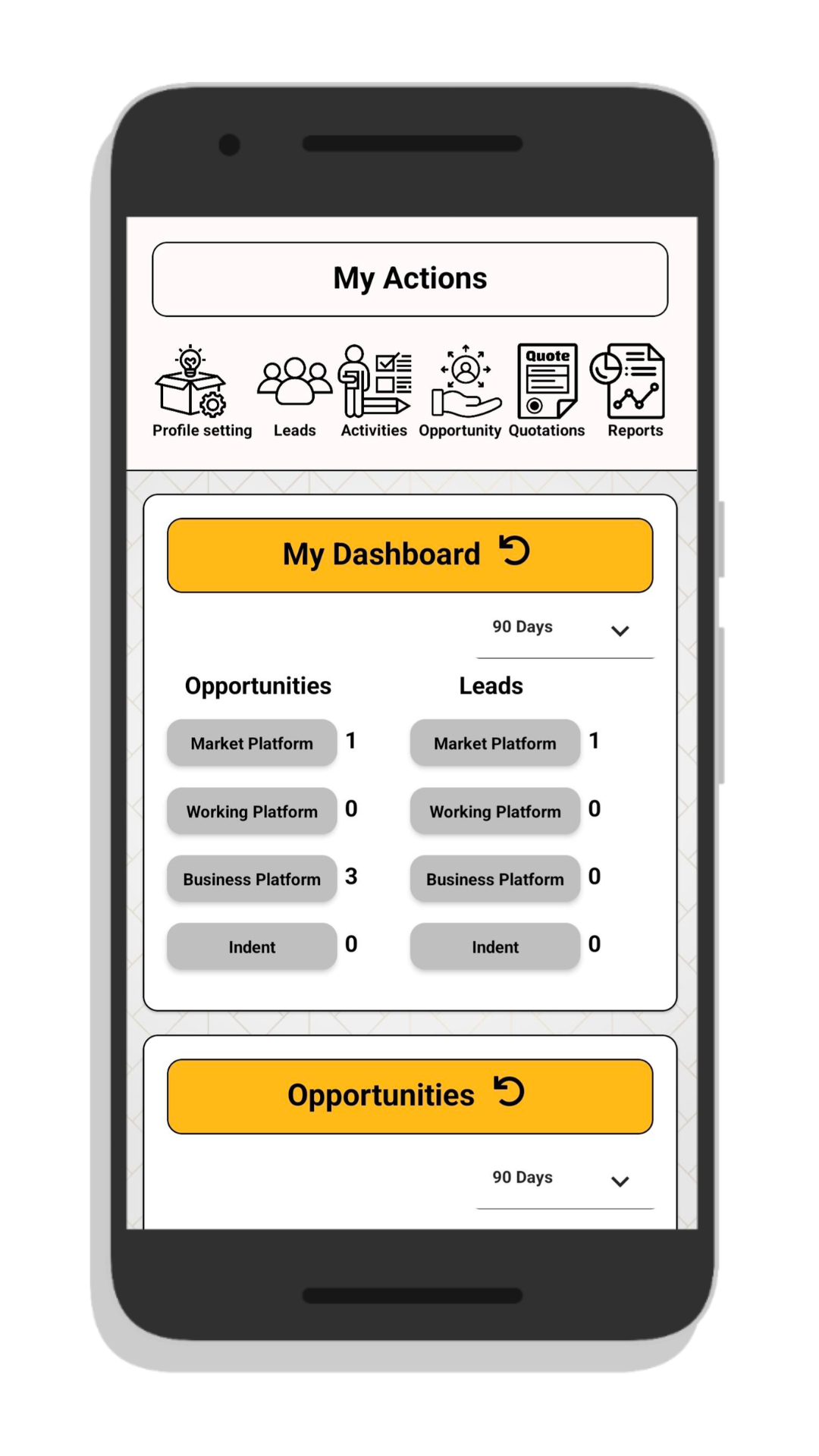

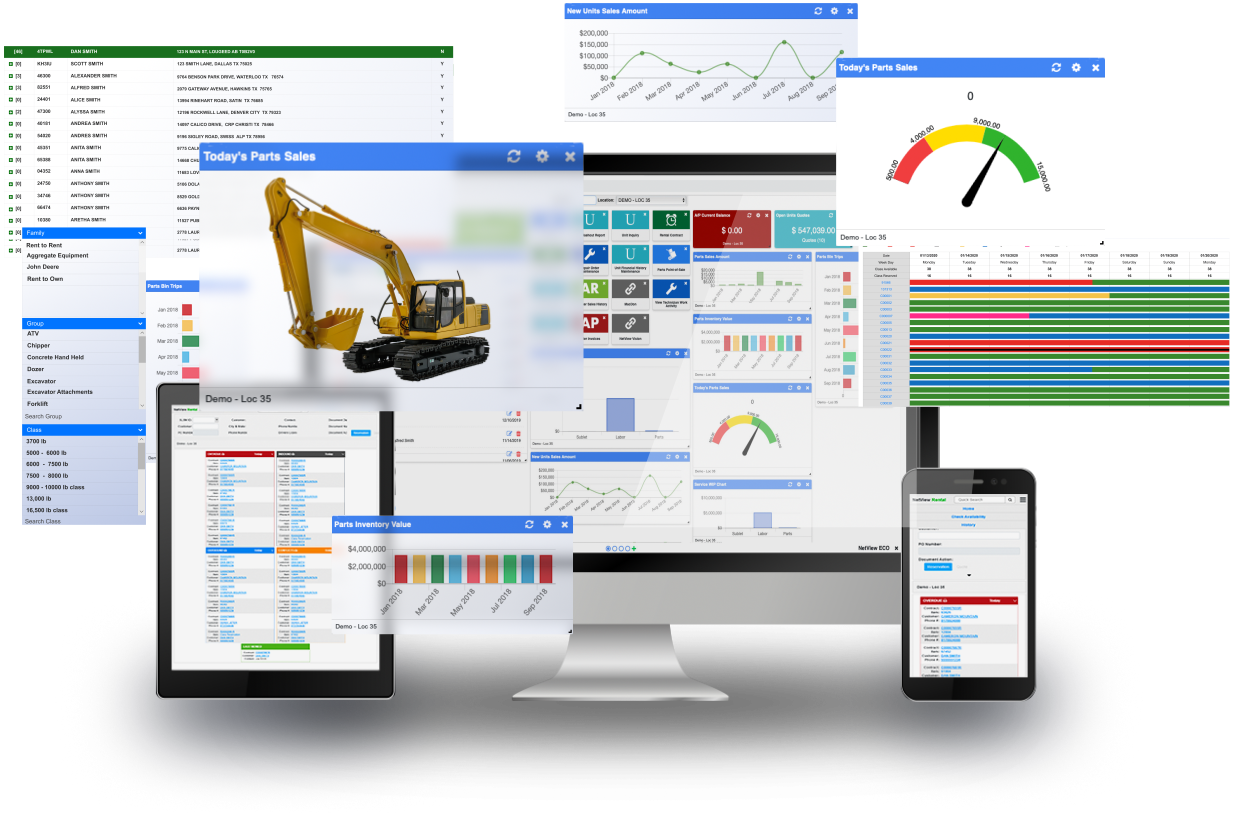

1. Integrated Dealer Management Systems (DMS)

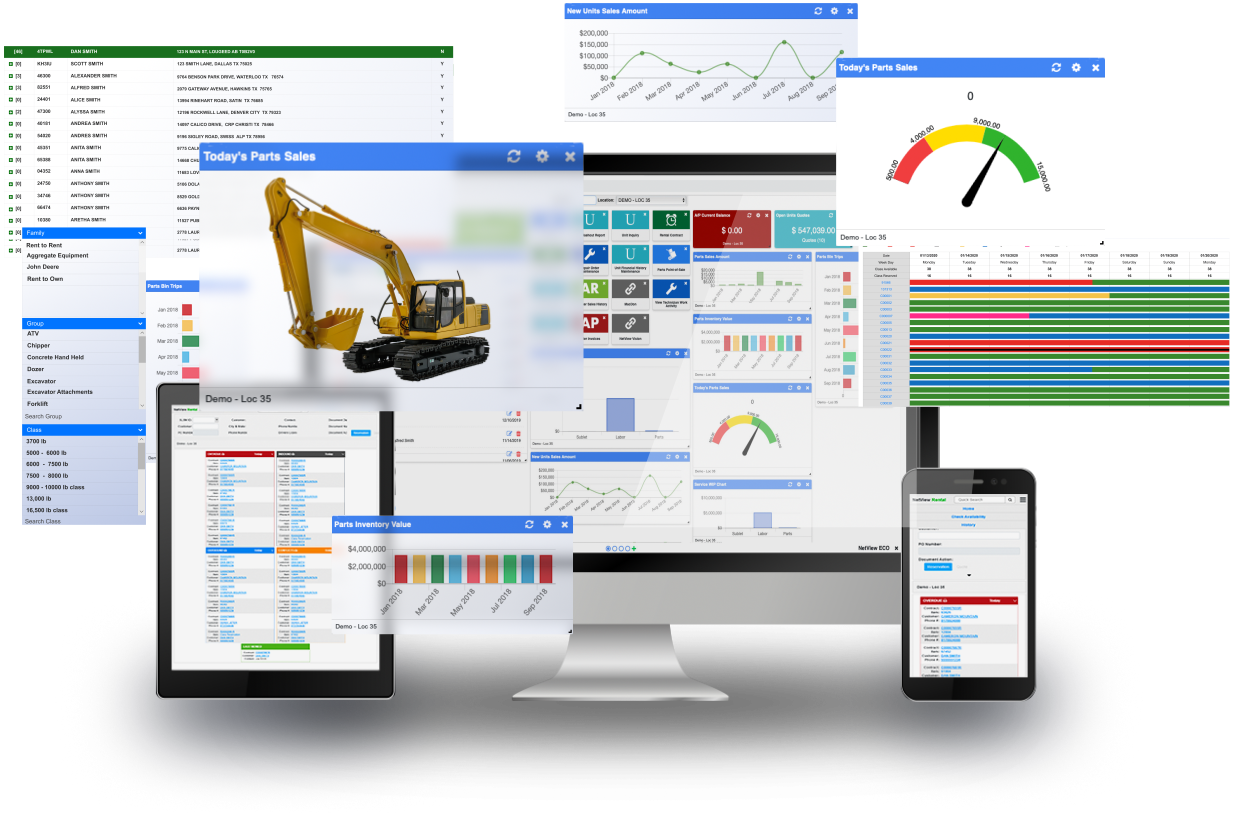

A Dealer Management System (DMS) is a type of ERP (Enterprise Resource Planning) system tailored for dealerships that sell and service construction equipment. These systems are essential for managing dealership operations efficiently, and digitisation has significantly enhanced their capabilities, making them more integrated, automated, and data-driven.

Key Features and Benefits:

- Seamless Integration with Manufacturer ERP: One of the most powerful features of modern Dealer Management Systems is their integration with the manufacturer's ERP system. This allows for a smooth exchange of data between the manufacturer and the dealer in real time. Data such as pricing, materials, equipment specifications, stock availability, and customer information is automatically shared between both parties, reducing the chances of errors and improving operational efficiency.

- Real-Time Updates: Manufacturers can update critical data (like materials, pricing, and stock levels) in their system, which is then pushed out to the dealer management systems in real time. This ensures that dealerships have access to the most up-to-date information for pricing and inventory without the need for manual updates.

- Automated Purchase and Sales Orders: When a dealer creates a Purchase Order or a Sales Invoice, it is automatically reflected in the manufacturer’s ERP system as a Sales Order or Payment Advice. This automation eliminates the need for duplicate data entry, saving time and reducing the likelihood of errors. Similarly, Service Orders are automatically generated when maintenance requests are made, streamlining the service management process.

- Improved Inventory Management: With real-time data on stock levels, dealerships can avoid overstocking or understocking parts and equipment, which ultimately reduces the carrying cost and enhances the customer experience. Having access to this information also helps dealers plan better for seasonal fluctuations or special project requirements.

- Enhanced Reporting and Analytics:Integrated DMS systems generate a wide range of reports, such as sales trends, service data, inventory levels, and financial performance. These reports provide valuable insights into dealership performance and help managers make informed decisions on stock purchases, promotions, and customer outreach. Dashboards that consolidate this data provide a clear, real-time overview of the business, aiding faster decision-making.

Example:

HBS Systems, a leading provider of Dealer Management Software, provides a robust solution for construction equipment dealerships. Their platform is designed to simplify dealership operations by providing integrated modules for sales, service, inventory, and reporting. With HBS Systems, dealerships can create opportunities, manage customer sales orders, track service orders, and generate invoices—all in one place.

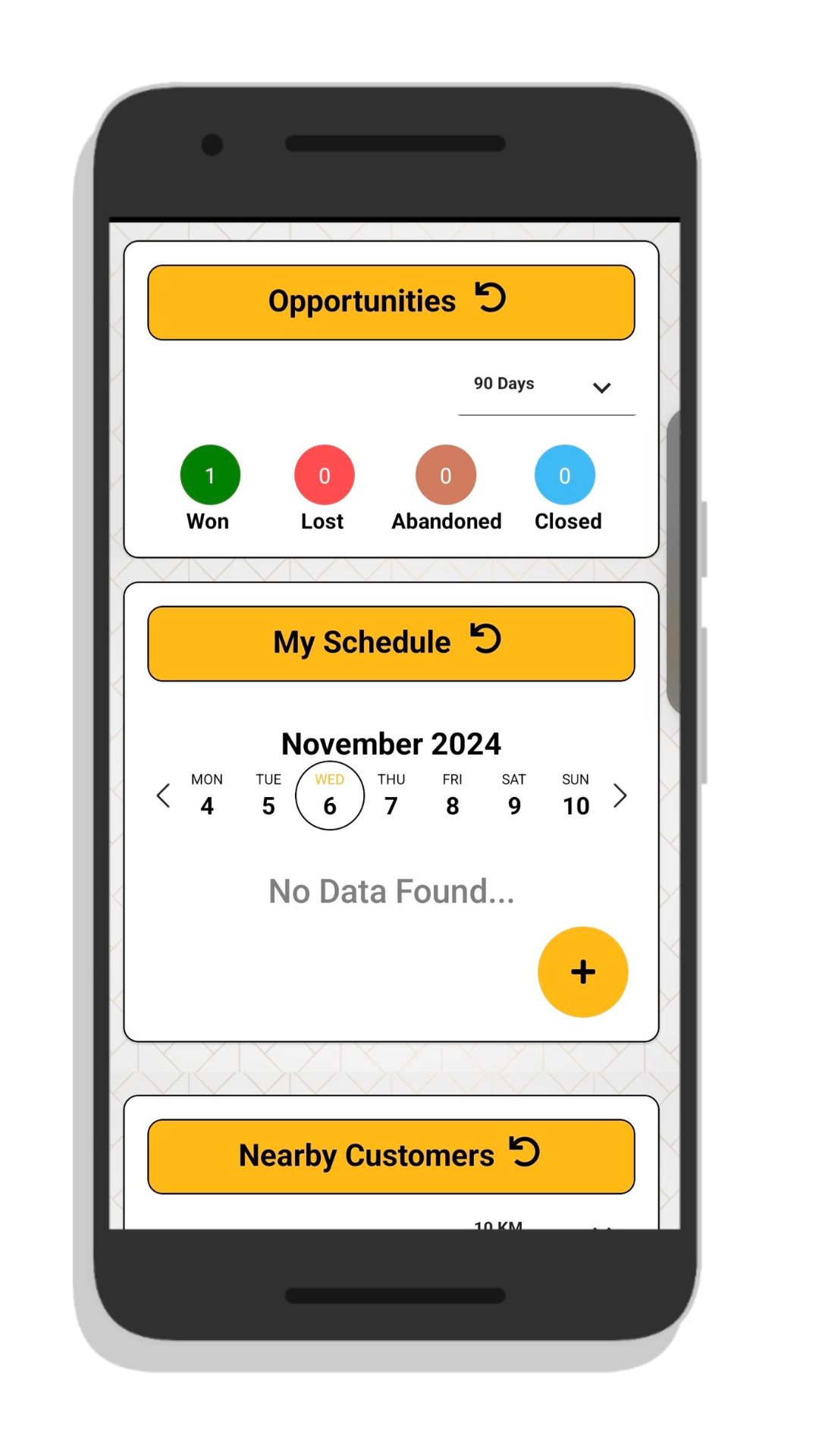

Mobile apps for Customer Relationship Management:

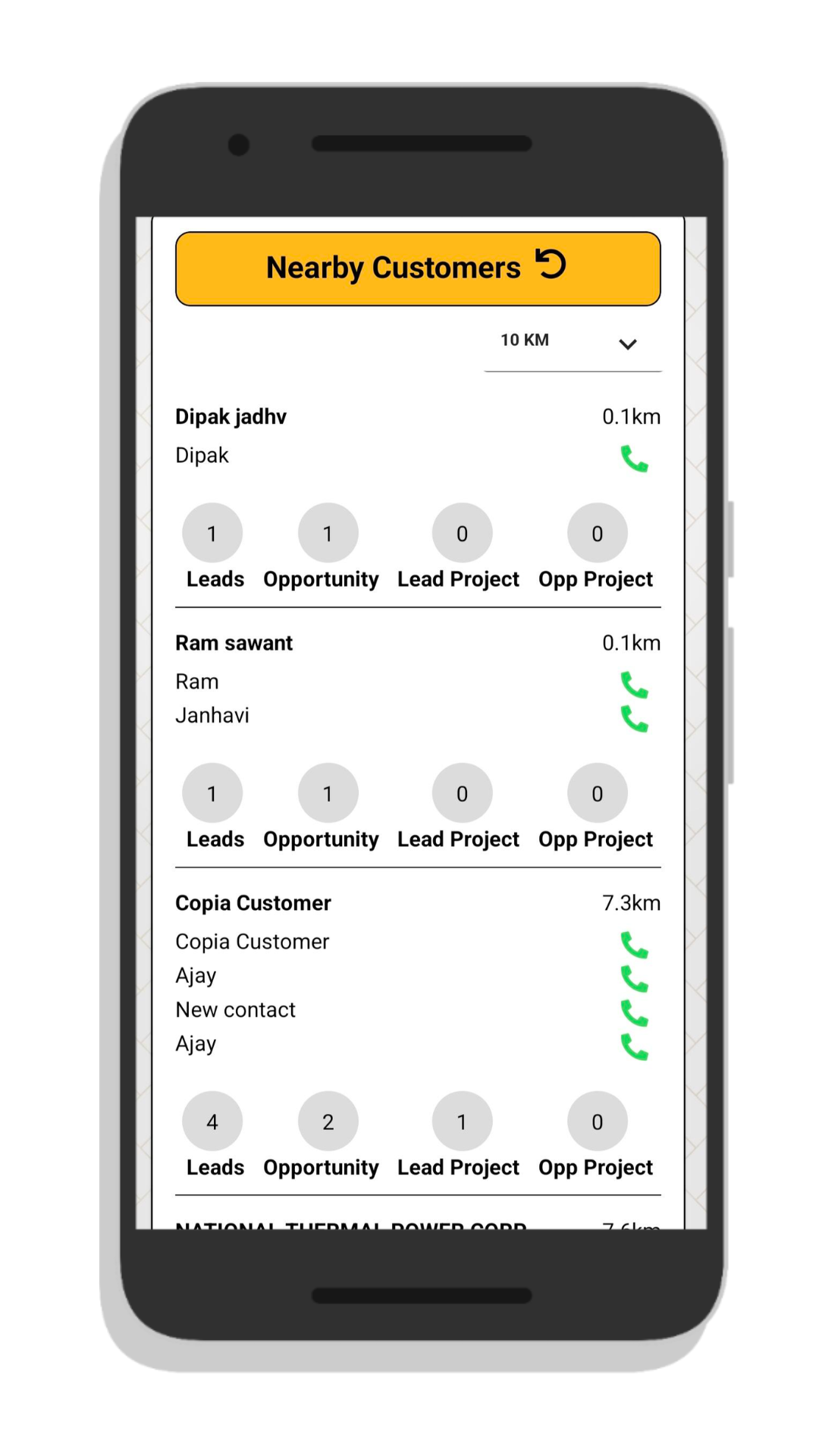

- Customer Relationship Management (CRM) is critical in the construction equipment industry, where sales and service often happen on-site rather than in an office. As construction projects are typically located at remote sites, the ability to manage customer relationships and service requests efficiently on the go has become increasingly important.

Key Features and Benefits:

- On-the-Go Data Capture:Mobile CRM apps allow sales and service teams to capture essential customer data directly from the field. By reducing the need to return to the office for paperwork, employees can spend more time on job sites, improving productivity. All data is synced with the central system in real time, ensuring that all stakeholders have access to up-to-date customer information.

- Increased Productivity: Mobile apps enable sales and service teams to manage their tasks, track customer interactions, and log service reports directly from the field. This means less time spent on administrative tasks and more time focused on customer engagement and service delivery. For example, service engineers can record repair data directly into the app, reducing the risk of errors and omissions.

- Faster Communication and Decision-Making: Mobile CRM apps facilitate instant communication between field employees, dealers, and manufacturers. Sales reps can update a customer’s status, log issues, and escalate problems all within the app. This leads to faster decision-making and improved service delivery.

- Employee Task and Performance Tracking:Many CRM apps also allow for the management of employee attendance, performance, and task completion. Sales and service personnel can submit daily reports, log service hours, and even update their travel itineraries, which helps improve operational oversight and reduces the need for manual tracking.

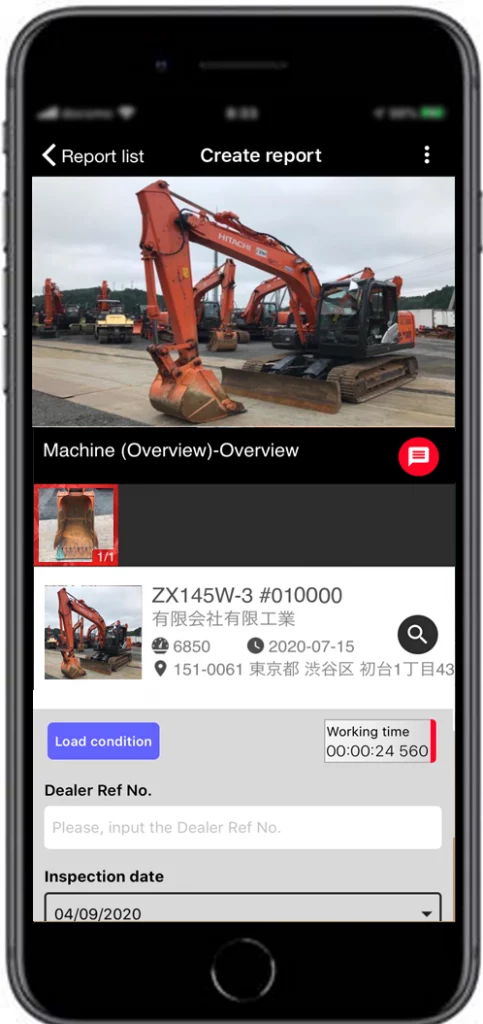

Example:

- The Consite Shot app by Hitachi Construction Machinery is an excellent example of a mobile CRM app that improves service operations. The app guides service engineers through equipment inspections by providing a checklist of parameters to check, ensuring that no important detail is missed. It allows engineers to upload photos of issues, generating detailed reports that can help with future servicing and parts recommendations.

3. Customer Self-Service Apps:

Customer Self-Service Apps have become increasingly popular in the construction equipment industry. These apps empower customers to manage their equipment needs, make purchases, and schedule services without needing to interact directly with sales or service representatives.

Key Features and Benefits:

- Ease of Access: Customers can access important information such asequipment brochures, quotations, service schedules, and parts availability all from the app. This allows them to make informed decisions without the need to contact a dealership or service center.

- Service Booking and Parts Ordering: Customers can use the app to book service appointments or order spare parts, which helps streamline service delivery and ensures that customers can manage their equipment without delays. Service reminders and notifications for periodic maintenance help ensure that equipment is serviced on time, preventing potential breakdowns.

- Cost-Effective Communication: These apps are a cost-effective way for manufacturers and dealers to communicate with customers. They can push notifications about new products, updates, promotions, or even video demonstrations directly to customers’ devices.

- Incentive Programs: To encourage customers to use these self-service apps, manufacturers often offer incentives, such as discounts or loyalty points, for customers who book services or order parts through the app.

Current Status and Challenges:

While these apps are still in the early stages of adoption, their usage is gradually increasing. In outdoor industries like construction, physical interactions and on-site engagements are still critical, which can hinder widespread adoption. However, as more customers see the convenience and benefits, especially for spare parts ordering and maintenance requests, these apps will likely gain traction.

4. Telematics Apps for Fleet Management

Telematics technology has revolutionised how companies manage large fleets of construction equipment.Telematics apps provide fleet managers with real-time data on fleet performance, equipment location, usage hours, and maintenance needs—all from their mobile device or desktop.

Key Features and Benefits:

- Real-Time Location Tracking: With GPS integration, telematics apps allow fleet managers to track the exact location of each piece of equipment. This is especially useful in large-scale construction projects where equipment may be spread across multiple job sites. Real-time tracking helps prevent equipment theft and ensures that resources are used efficiently.

- Operational Status Monitoring: Telematics apps provide detailed information about the operational status of equipment, such as whether it is working or idle. This data helps managers optimise usage, reduce downtime, and allocate equipment more efficiently across job sites.

- Maintenance Alerts and Fault Codes: Telematics systems can monitor critical parameters of equipment, including engine performance, fuel levels, and hydraulic pressure. If any anomalies are detected, the system sends alerts to fleet managers, enabling them to schedule maintenance before a major failure occurs. This reduces unplanned downtime and extends the lifespan of equipment.

- Data-Driven Decisions: Telematics apps also provide data on equipment usage, which can be used to make informed decisions on fleet management. By understanding usage patterns, fleet managers can decide when to rotate equipment, replace older machines, or invest in additional units.

Example:

Telematics apps are widely used by large fleet in industries like construction, where maintaining high levels of productivity is critical. Fleet owners can remotely monitor all their equipment, set up maintenance schedules, and manage repair needs, leading to fewer unplanned outages and more efficient operations.

5. The Future of Digitisation in Operations

Looking ahead, the future of digitisation in the construction equipment industry is poised for even greater advancements, driven by the integration of artificial intelligence (AI), machine learning, and cloud computing. These technologies will provide more advanced predictive analytics, automate even more processes, and enhance the overall digital ecosystem within the industry.

- Predictive Maintenance: : With the use of AI, maintenance predictions will be more accurate, helping companies better anticipate equipment failures and reduce downtime.

- Blockchain for Transactions: Blockchain may play a role in securely recording equipment transactions, including sales, leasing, and parts procurement. This could reduce fraud and improve the transparency of business operations.

- Augmented Reality (AR): AR could transform service applications by enabling technicians to visually inspect equipment and provide real-time data overlays during repairs.

Conclusion

Digitisation is driving a revolution in the operations of the construction equipment industry. Through Integrated Dealer Management Systems, Mobile CRM apps, Customer Self-Service Portals, and Telematics for fleet management, businesses are becoming more efficient, responsive, and data-driven. By embracing these technologies, manufacturers, dealers, and fleet owners can streamline operations, reduce costs, and ultimately provide better services to their customers. As we move forward, the continued evolution of AI, IoT, and cloud technologies promises to take digitisation to new heights, enhancing the way the construction equipment industry operates and interacts with customers.