Digitisation in Construction Equipment Industry

The Construction Equipment Industry has made great strides in digitisation in recent past. Digitisation in the Construction Equipment Industry can be broadly categorised into following types:

- Digitisation in Equipment

- Digitisation in Operations

In this blog, we will see in detail, the Digitisation in Equipment.

Digitisation in Construction Equipment started with electronic controls of engines and hydraulic systems. Equipment were fitted with on- board computers ( called as “ Control Units” )that used to :

- Give alarms if any of the equipment parameters went beyond normal limits. These parameters were engine oil temperatures, engine speeds, hydraulic oil pressure and temperatures, lubricant and fuel levels and so on.

- Stored real time data of these parameters along with other details such as operating time and hours, modes of operations, alarms, fault codes and so on. The data from these on- board computers could be downloaded by a palm – top or laptop and analysed as and when required.

This helped diagnostics and preventive maintenance to a large extent.

With the advancement of Information and Communications Technology, the data from the onboard computers was made available through satellite communication. This information was costly and not accessible to everyone. Now as cellular networks have exponentially expanded, this data is democratised and is available to everyone on a real time basis on their mobile phones at a very low cost. With the development of Geographical position systems ( GPS), the exact location and movement of the equipment can be traced.

There are huge benefits of digitisation in Construction Equipment namely:

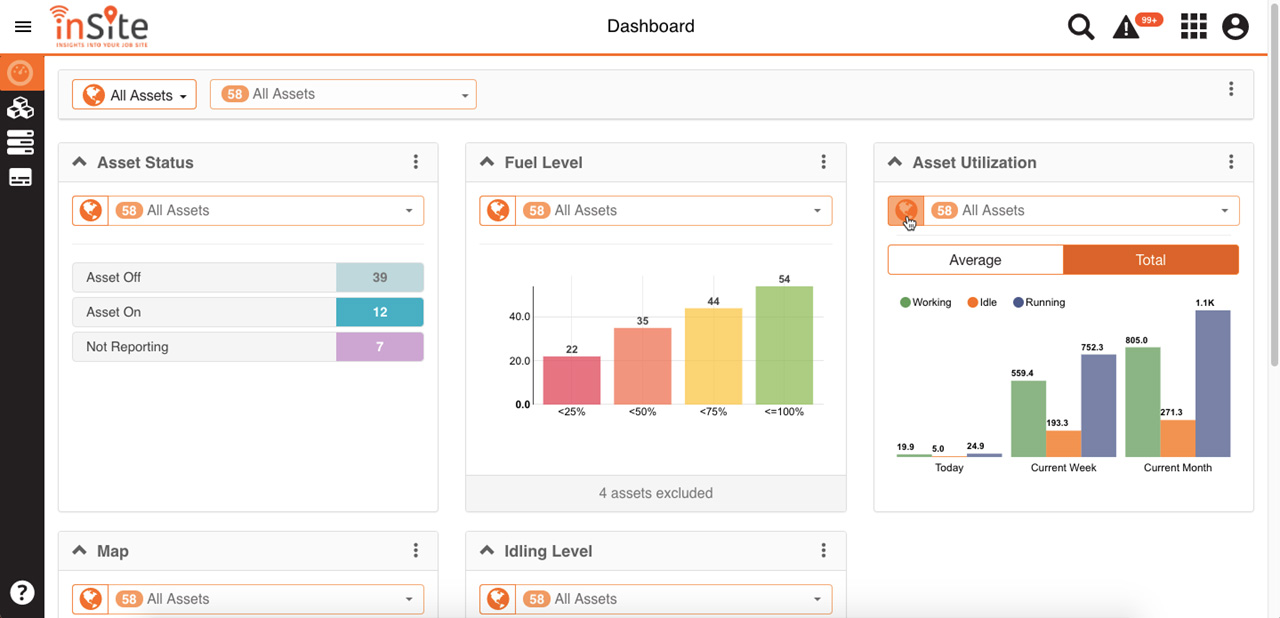

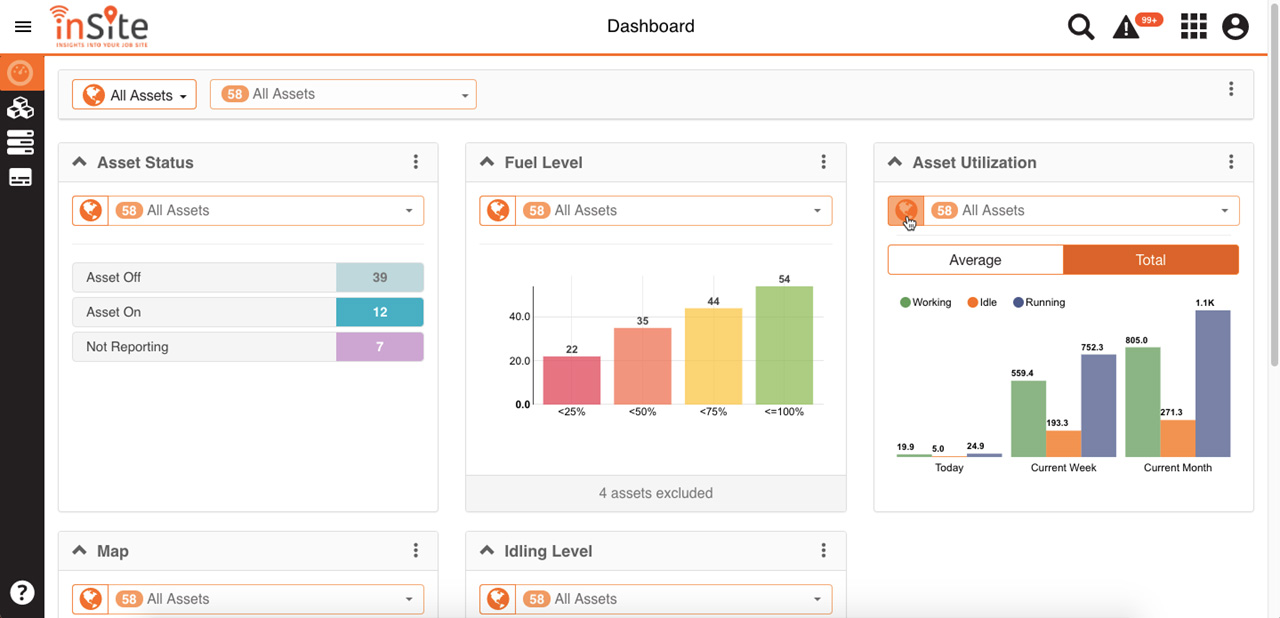

- Real time availability of data: The exact location of the equipment, Hour meter reading, whether it is working or idle is all available in real time on mobile device. This helps the contractor or fleet operator monitor the location and operations of his equipment.

- Breakdown prevention: On- board computer throws alarms so that equipment can be stopped before failure takes place. Even if the operator misses the alarm, the owner or supervisor gets the alarm and can prevent major failures in equipment. This helps prevent unforeseen losses and breakdown of equipment. Typical alarms are low fuel level, low engine oil level, high engine oil temperature, high hydraulic oil pressure, high hydraulic oil temperature and so on…

- Help in Predictive Maintenance: Data taken from on – board system can be analysed which can be used to predict failures. The data can predict health of various components of the equipment and predictive maintenance can be undertaken which can prevent further costly failures. Example: Consistent high hydraulic pressure or temperature can be an indicator of early hydraulic system failure and hence it would be prudent to inspect the hydraulic system of such equipment. Another example is more than the threshold level of travel in equipment can lead to early undercarriage failure. Undercarriage of such equipment need to be inspected.

- Preventive maintenance: The on- board system throws alerts for periodic preventive maintenance such as hydraulic or engine oil and filters changes so that these maintenances are not missed thus protecting the equipment from major failures.

- Safety: The real time location aids greatly in ensuring safety of equipment.

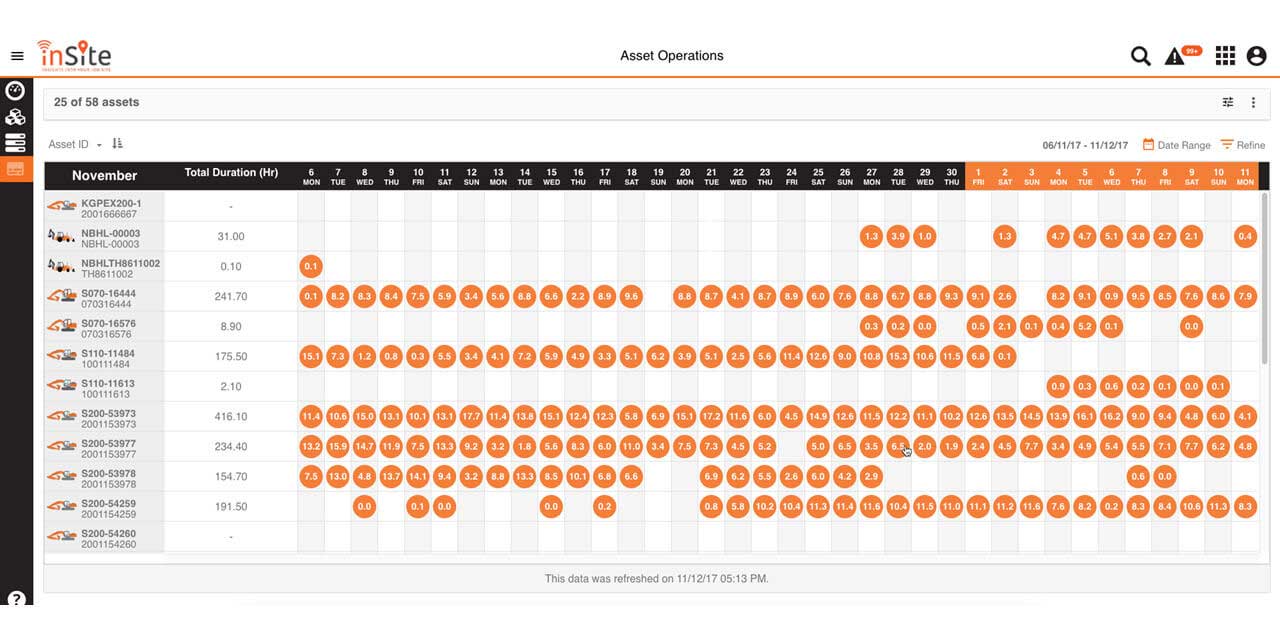

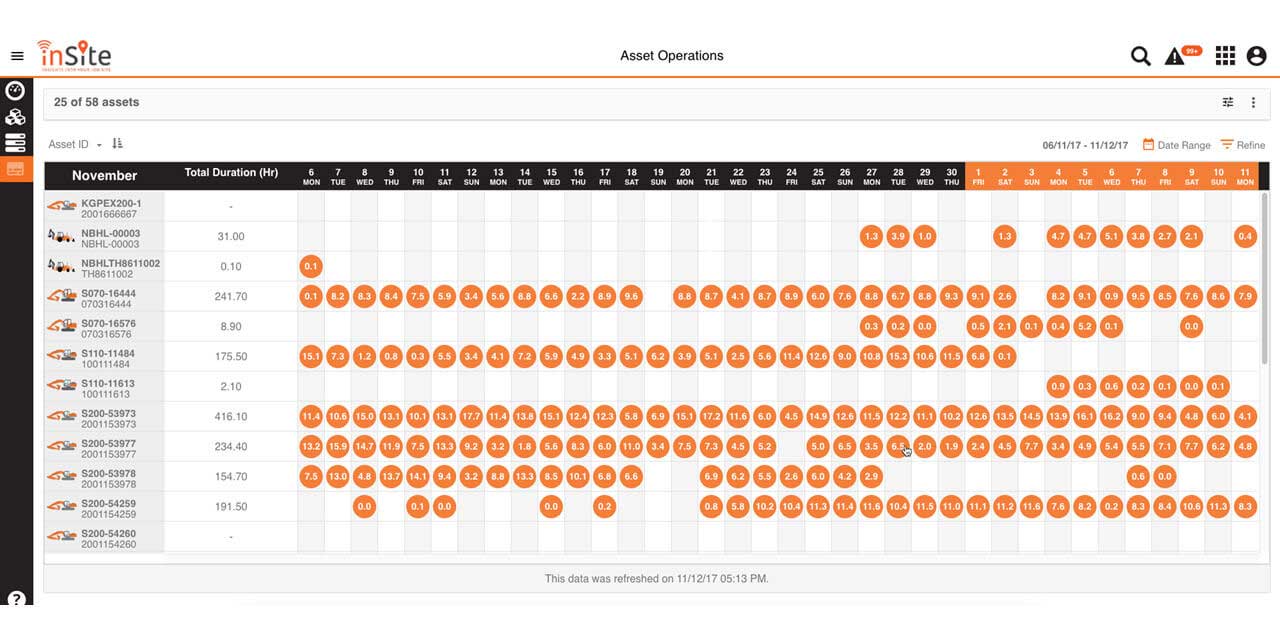

- Log of equipment working: Analytical tools give a complete log of equipment working with location and data of all parameters with good visualisation. This helps the owner/ operator with a visual snapshot of equipment working for a particular time period.

- Information on critical parameters:The on- board system can give instantaneous and periodical formation about critical parameters such as fuel consumption which is otherwise difficult to calculate with any degree of accuracy. This alert is real – time so if fuel consumption is abnormally high, corrective action can be taken as otherwise by manual systems, there is a lag in information availability.

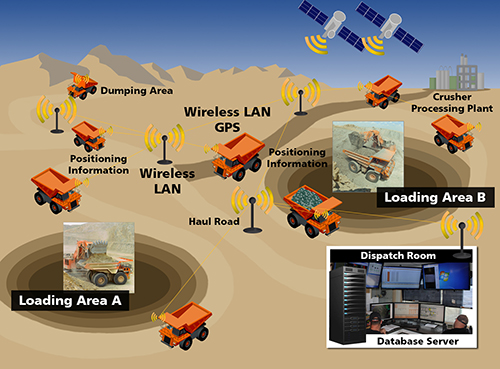

source: Heavy Construction Machine Monitoring System Remotely

source: Heavy Construction Machine Monitoring System Remotely - Telematics: Telematics is an emerging field of integrating equipment data from sensors through Mobile communication and internet into a user- friendly rendering and visualisation on any device such as laptop or mobile device. There have been great advancements in all the building blocks of telematics such as Sensor technologies, mobile communication, internet and data analytics. This offers great value to equipment users, maintenance managers and Equipment manufacturers.

There are great possibilities for future automation in telematics such as integration with manufacturer’s or dealer’s CRM system that can throw automatic alerts and quotations for periodic services to both the customer and the dealer/ manufacturer, deployment of equipment for emergency works in nearby areas during natural disasters and so on. Almost all Construction and Mining Equipment manufacturers in India give telematics as a standard fitment under different brand names in their equipment as per below table:

| Manufacturer | Manufacturer Telematics system |

|---|

| Tata Hitachi | Tata Hitachi Consite (for the ‘Zaxis series’ equipment) |

| Tata Hitachi | Tata Hitachi Insite( for the ‘EX series’ equipment) |

| JCB | Livelink |

| Komatsu | Komtrax |

| Caterpillar | Cat R Connect |

| Volvo | CareTrack |

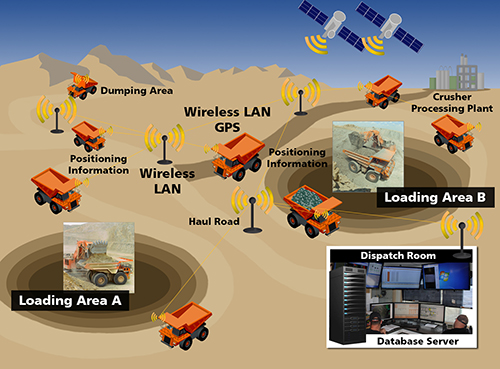

- Mining Fleet Management Systems : The greatest return on digitisation investment is found in continuous production mining operations where safety and productivity are of paramount importance. Fleet management softwares can determine the number of equipment requirement depending upon various mine factors such as gradient, productivity of excavators, haulage capacity of dumpers, lead distance, output required, swing angle, mining bench heights and so on. These softwares perform complex calculations and give optimum requirement of the number of equipment required and their capacities.

Once the operations start, these fleet management systems form the heart of the mission critical production management system giving live real- time information about the entire equipment deployed. They can detect any breakdown live and immediate corrective action can be taken. They also have peer- to- peer communication facilities that help in safety by providing proximity detection, collision avoidance systems and so on. One can track production on real- time basis.

Reliable wireless systems and robust wireless devices form the backbone of the communications system for fleet management systems in mining where the mining sites are remotely located.

Many equipment manufacturers have integrated Fleet Management systems as a part of their standard offering. Mining giant Hitachi Construction Machinery has acquired fleet management solutions vendor Wenco. Hitachi’s deep understanding and knowledge of mining equipment and mining operations combined with the IoT and Big Data Analytics expertise of Wenco has helped create many innovative solutions for the big mining industry.

- Autonomous equipment: Further frontiers of digitisation in Construction Equipment lies in development of Autonomous Equipment especially for mining operations. The level of autonomy can differ with remote control of acceleration and braking to totally driverless remote operated equipment. Most of the these automated equipment will be Battery operated Electric Equipment that will integrate equipment operating parameters such as Battery Management systems that will have a real- time control and information of the equipment. Thus we can find that digitisation in Construction and mining Equipment has already become an integral part of equipment and a lot more development is in progress to improve safety, productivity and maintenance effectiveness of equipment.

source: Heavy Construction Machine Monitoring System Remotely

source: Heavy Construction Machine Monitoring System Remotely